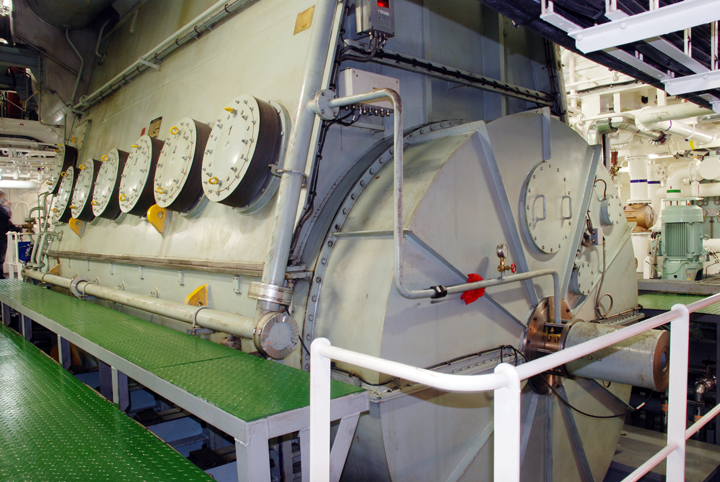

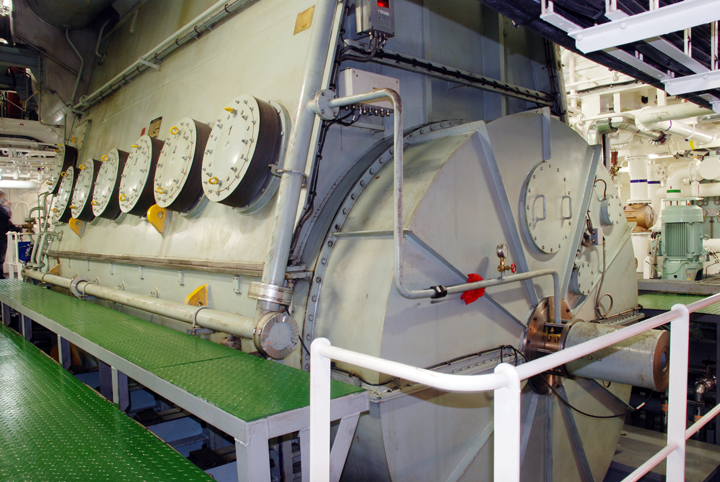

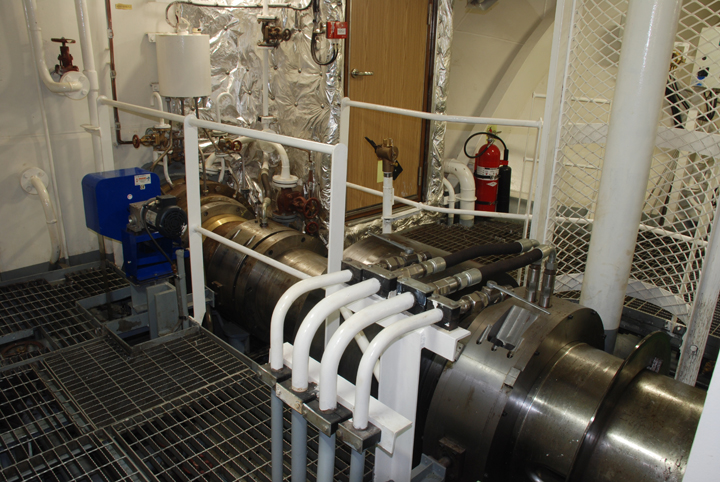

Looking aft from the starboard side at the new diesel

Duluth, December 22, 2012, Image 12-5216

Engine on

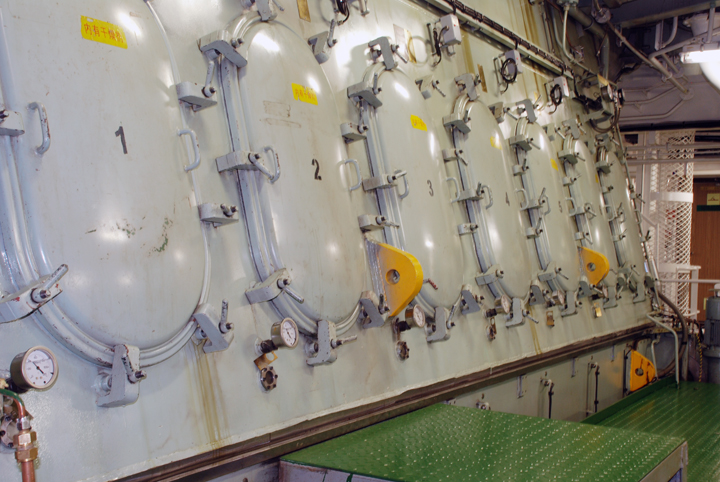

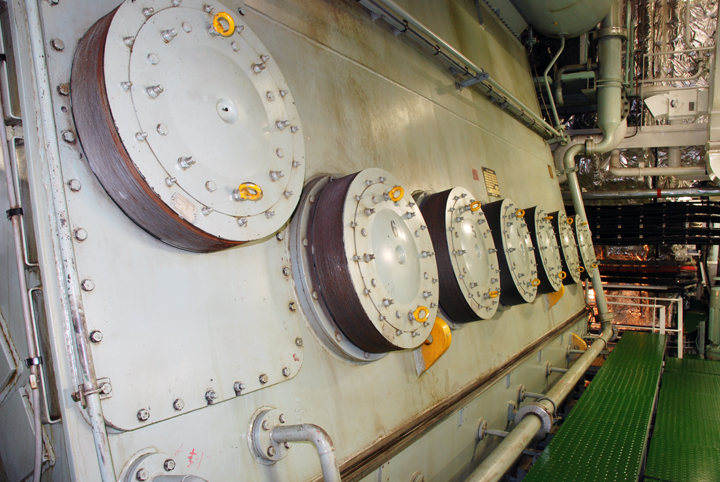

Baie St. Paul seen from the lower engine deck

Duluth, December 22, 2012, Image 12-5346

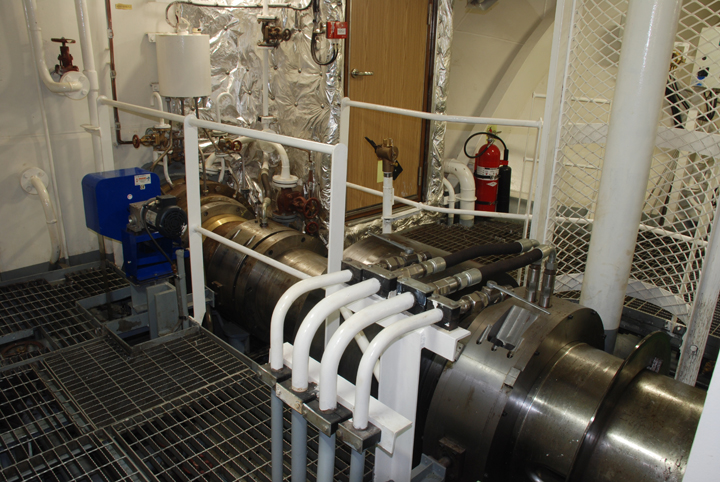

Propeller shaft on

Baie St. Paul

A new feature being used are non-metallic seawater lubricated propeller shaft (stern tube) bearings

The bearings used on the Trillium Class vessels are manufactured by Thordon Industries of Canada

Duluth, December 22, 2012, Image 12-5241

A closer look at the shaft.

Duluth, December 22, 2012, Image 12-5243

Looking aft from the port side at the new diesel

Duluth, December 22, 2012, Image 12-5221

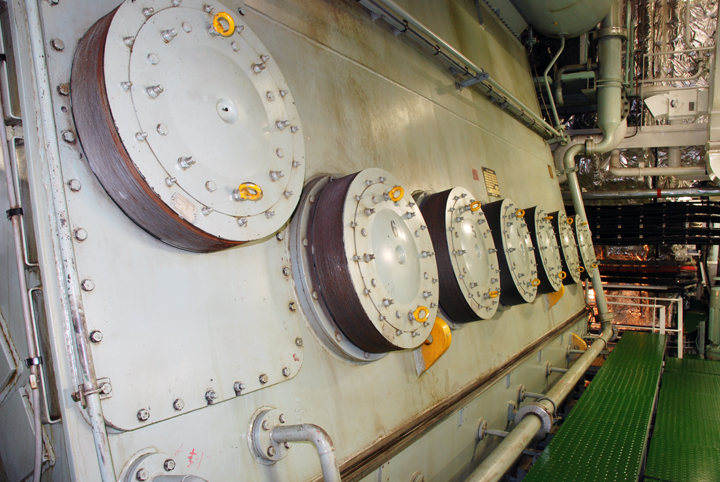

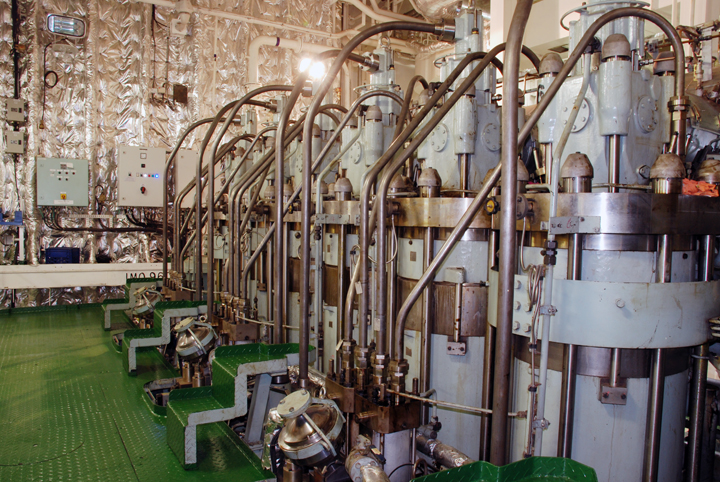

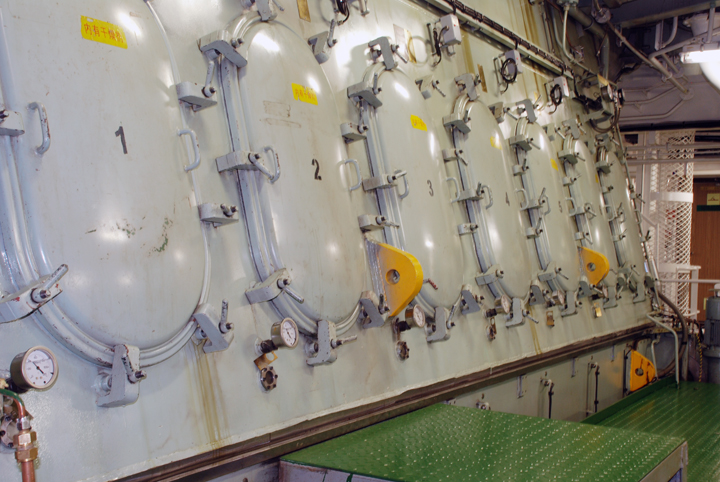

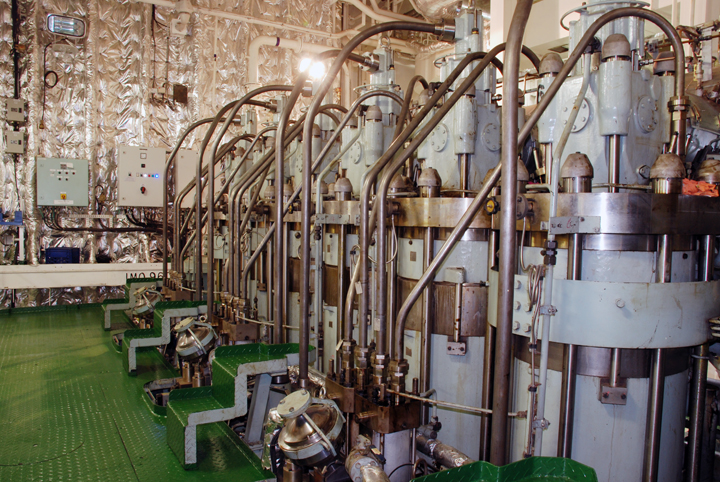

Cylinder heads on the main engine seen from the machinery deck

Duluth, December 22, 2012, Image 12-5248

Looking aft at cylinder heads

Duluth, December 22, 2012, Image 12-5252

Engine ontrol room on the

Baie St. PaulDuluth, December 22, 2012, Image 12-5253

One of the vessel's engineer's works with an engineering consultant

Duluth, December 22, 2012, Image 12-5260

Looking forward down the spacious, and clean, unloading tunnel. Unloading of cargo is done from a control room

above deck level. The only time personnel are needed in the tunnel is for cleaning and maintenance

Duluth, December 22, 2012, Image 12-5226

Looking aft in unloading tunnel toward the loop belt

The

Baie St. Paul has a two belt system

Duluth, December 22, 2012, Image 12-5230

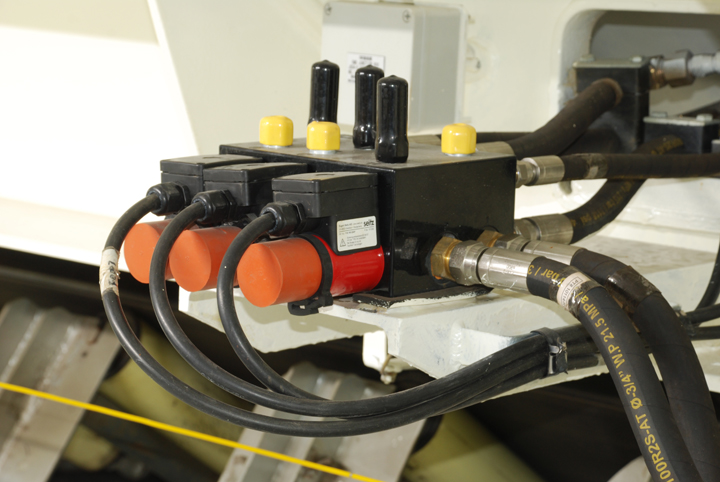

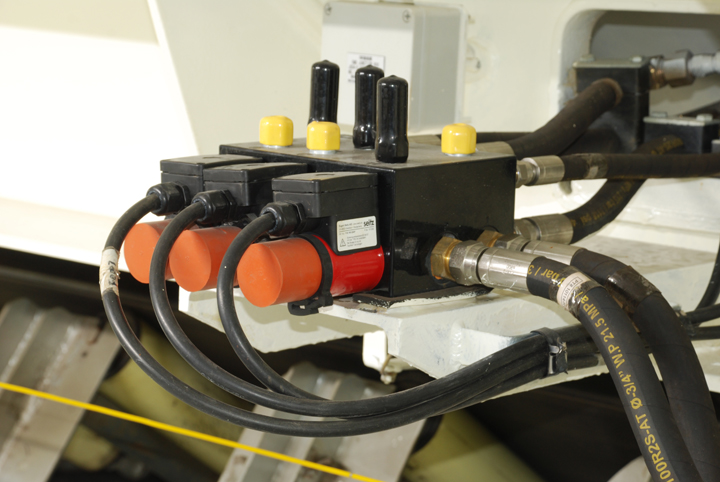

Manual controls for opening the cargo gates...now operated remotely from the control room

Duluth, December 22, 2012, Image 12-5233

A new feature on the Trillium Class vessels is a system of cameras located throughout the ship

This camera monitors the cargo tunnel

Duluth, December 22, 2012, Image 12-5230