Mike Romel, Chief Engineer, M/V

Manistee

Duluth, Sep 29, 2006, Image 06-9711

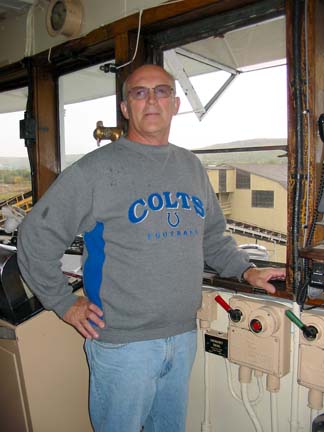

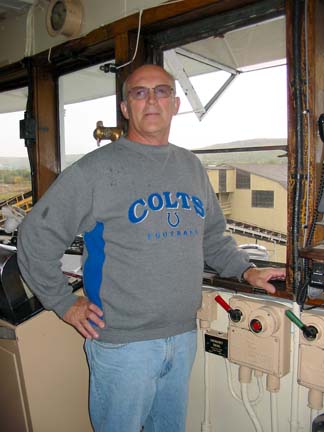

Captain Ronald Brezinski, M/V

Manistee

Duluth, Sep 29, 2006, Image 06-9720

The

Manistee, beginning to discharge its cargo of road salt at Hallett Dock 5 in Duluth.

Duluth, Sep 29, 2006, Image 06-9662

The salt was loaded in Cleveland at the Cargill dock. The greenish color is a

chemical agent put on the salt that helps it stick on the roads.

Duluth, Sep 29, 2006, Image 06-9684

The

Manistee has two unloading belts that deliver the cargo to a continuous

feed elevator system at the forward end of the ship.

Duluth, Sep 29, 2006, Image 06-9686

The elevator bucket system has become increasingly obsolete on the Great Lakes as technology

has moved to the continuous loop-belt systems on larger ships. For a ship the size of the

Manistee

the bucket system is very efficient and takes very little physical space, maximizing the amount of cargo capacity.

Duluth, Sep 29, 2006, Image 06-9705

The

Manistee, built in 1943, is in its 2nd year of operation for Grand River Navigation.

The vessel makes an average of 115 trips a year, but rarely makes runs up to Lake Superior.

Duluth, Sep 29, 2006, Image 06-9692

A portion of the 13,800 ton cargo of salt destined for the winter road season in northern Minnesota.

Duluth, Sep 29, 2006, Image 06-9702

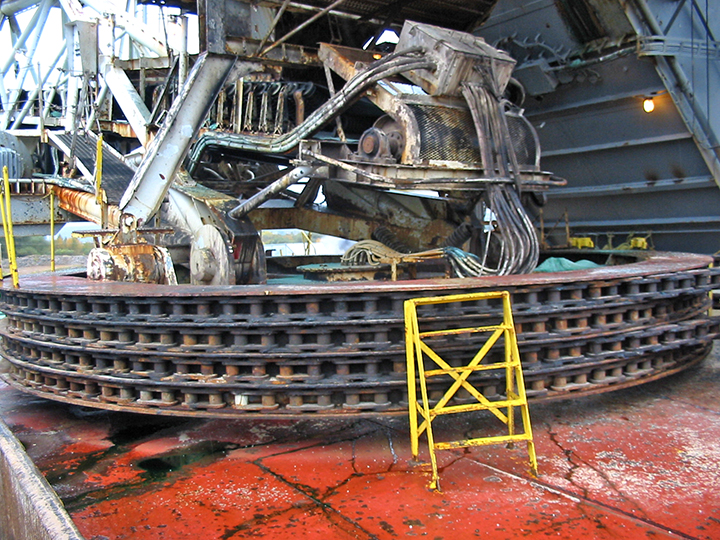

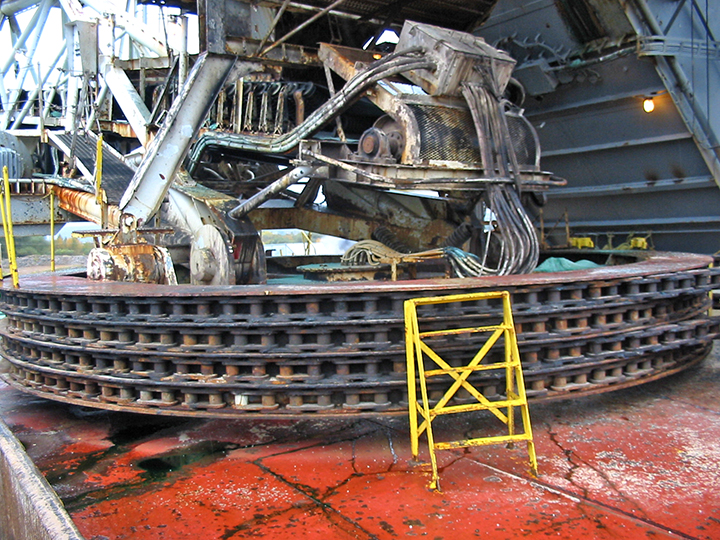

The

Manistee's unloading boom is mounted on a slewing table. Slewing tables, more common in the 1950s and 60s,

are nearly extinct on Great Lakes ships today. The

Manistee is likely the last one.

Duluth, Sep 29, 2006, Image 06-9682

Detail view of the chains on the slewing table. The table is used to rotate the unloading boom

to either the starboard, or port side of the vessel.

Duluth, Sep 29, 2006, Image 06-9739

Jeff Bowen, AB/Wheelsman

Duluth, Sep 29, 2006, Image 06-9676

Andrew Rose, Bosun

Duluth, Sep 29, 2006, Image 06-9677

After cabins of the

Manistee, from the spar deck. The

Manistee has 16 hatches and a capacity of approximately 16,000 tons.

Duluth, Sep 29, 2006, Image 06-9689

When the vessel was converted to a self-unloader in 1964, wings were added to the pilothouse for better visibility

when backing. On older ships like this, there is no "inside" entrance to the pilothouse...you have to go outside to go in.

Duluth, Sep 29, 2006, Image 06-9728

The big ship's wheel in the pilothouse, stationed behind the binnacle.

Duluth, Sep 29, 2006, Image 06-9719

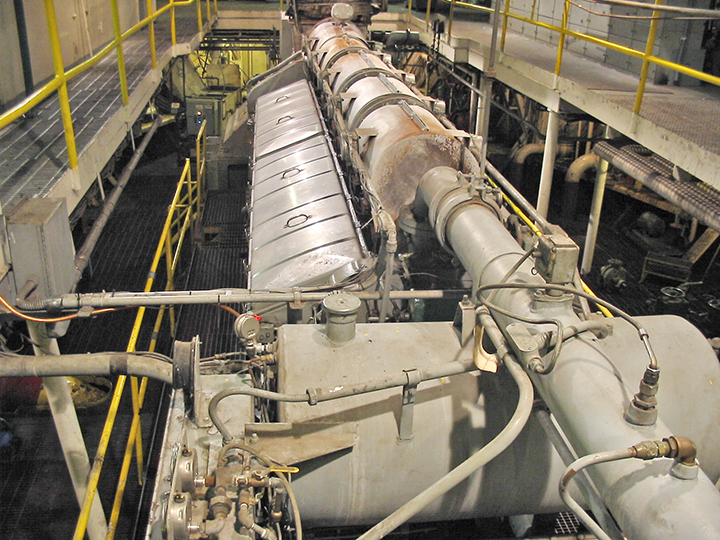

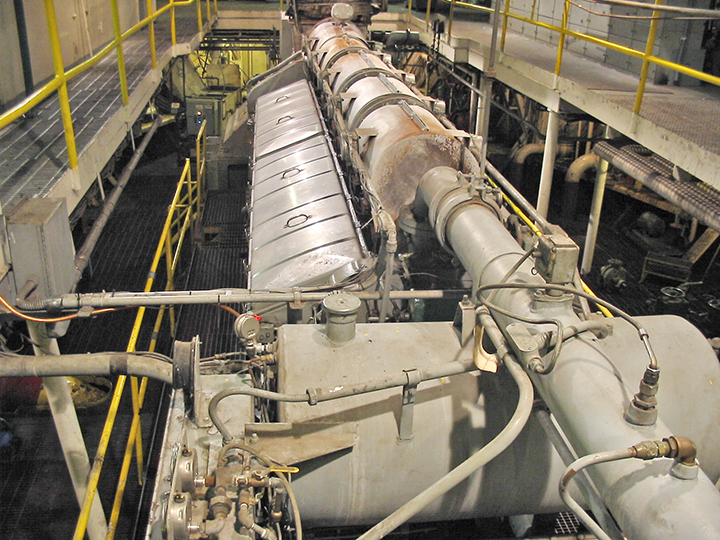

The

Manistee is powered by a 2950 HP General Motors diesel engine.

The engine was installed in 1976, replacing the ship's original triple

expansion engine and steam plant.

Duluth, Sep 29, 2006, Image 06-9697

Mike Wesenberg is the

Manistee's 1st Assistant Engineer. Mike began

sailing in 1988 as a 3rd Assistant aboard the

Cason J. Callaway.

The

Manistee carries a crew of 18.

Duluth, Sep 29, 2006, Image 06-9699

Additional

crew images from Manistee

The

Manistee departs the Hallett Dock, shifting to load its second cargo

of taconite this season. The

Manistee normally trades on Lake Michigan,

Lake Huron and Lake Erie, hauling limestone, coal, foundry sand, slag, pet coke, and salt.

Duluth, Sep 29, 2006, Image 06-9772